The Chemalux 600DL System is a small but complete, fully computerized digital surfacing lab system specially designed for small to mid-size labs. The system offers a full range of capabilities for Rx and freeform production even including hard coating and anti-reflection coating in a small space less than 10 x 20 square feet. Precise optics, digitally surfaced lenses, no more laps, in-line production, robust coatings are the part of the benefits of the system. In addition, the System has been equipped with the software to make Aspheres, Slab-offs/Slab-ons, Bifocals, High Minus Lenticulars, 8 or 10 base Wraps at the same cost as regular Rx lenses.

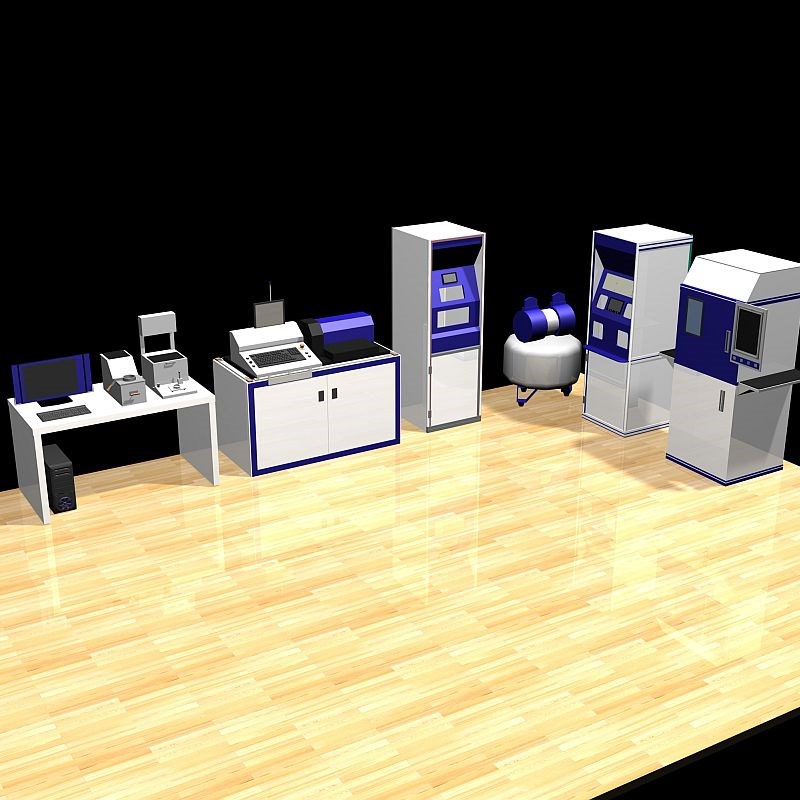

Equipment in the Systems

Unity MAX Blocker: The Unity MAX blocker combines highly accurate lens layout and blocking into a single, compact station. Unity MAX offers the precision and reliability of software-based lens alignment.

RxD Lathe: Generates surfaces ready for Soft Lap Polishing; Generates traditional back-surface base curves, cylinder and prism without prism blocking

NSLP Soft Lap Polisher: Polishes concave, convex or combination lenses; Eliminates need for hard tooling when used with the DAC RxD Lathe; One size soft lap tool polishes all lens designs; Programmable control of stroke, pressure, time, rotation of lap and lens.

600 SRAR Coating Machine: Fabricate scratch resistant coatings and anti- reflective coatings in the same machine at the same run; Incorporate high pressure water washing; Program to make the coating lens by lens not batch by batch.

Process Flow

Step 1: Design Rx optics based on individualized measurements such as frame dimensions, vertex distance, and pantoscopic tilt;

Step 2: Use special Rx calculation management software to convert a progressive surface design into a set of numbers called a points file or cutting file. Transfer this data file to Chemalux 600DL RxD Lathe;

Step 3: Block the semifinished lens blank using Chemalux Unity Max Blocker

Step 4: Using RxD Lathe to cut the lens design directly onto the blocked lens from the loaded data to produce aspheres, atorics or complex surfaces.

Step 5: After the complex surfaces are cut by diamond tools, the complex surfaces will be polished to optical quality by soft polishing using NSLP Soft Lap Polisher.

Step 6: The polished lens is de-blocked and coated with scratch resistant coating and anti-reflective coating using 600 SRAR Coating Machine; After being cured, the lenses are ready to edge.

Key Features

- A complete digital surfacing lab system including hard coating & AR coating

- The lowest cost system in the world

- The smallest digital surfacing system in the world

- Full automation potential even with coatings (SR & AR)

- Extremely smooth surface ready to coat (for CR-39 and PC) or to polish (high index) using patented Reaction Eliminator reduces machine vibration